箱体工艺分析

箱体工艺外文翻译

Title: Translation of Box Packaging Techniques

Introduction:

Box packaging is an essential aspect of product manufacturing and distribution. The process involves designing, constructing, and decorating boxes to safely hold and present various items. This translation aims to provide an overview of box packaging techniques and their significance in different industries.

1. Types of Box Packaging Techniques:

1.1. Folded Cartons:

Folded cartons are one of the most common types of boxes used for packaging. They are created by folding flat sheets of cardboard or paperboard into a box shape. Folded cartons can be customized in various sizes, shapes, and designs to suit the specific product requirements.

1.2. Rigid Boxes:

Rigid boxes, also known as setup boxes, are sturdier and more durable than folded cartons. They are made from thicker materials such as cardboard, chipboard, or corrugated board. Rigid boxes provide better protection for fragile or highvalue items.

1.3. Corrugated Boxes:

Corrugated boxes are widely used for shipping and transportation purposes. They comprise three layers an inner liner, an outer liner, and a fluted layer in between. The fluted layer provides cushioning and shock absorption, making corrugated boxes ideal for protecting goods during transit.

2. Box Construction Techniques:

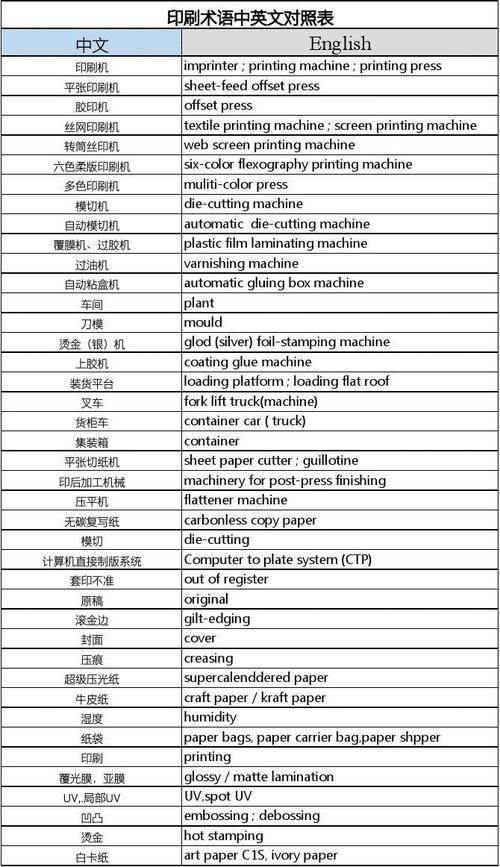

2.1. DieCutting:

Diecutting is a common technique used to create precise, uniform shapes in box packaging. It involves using a die, a specialized tool, to cut out specific patterns or designs on the box material.

2.2. Gluing:

Gluing is the process of joining different parts of the box together. Various adhesive techniques, such as hot glue, cold glue, or pressuresensitive adhesive, can be used depending on the box material and desired strength.

2.3. Folding and Tucking:

Folded cartons are typically designed with creases or prescored lines to facilitate easy folding and tucking. This technique ensures that the box can be assembled quickly and securely.

3. Box Decoration Techniques:

3.1. Printing:

Printing plays a crucial role in enhancing the appearance of boxes. Different printing methods, such as offset printing, flexography, or digital printing, can be used to apply graphics, logos, text, and images onto the box surface.

3.2. Embossing and Debossing:

Embossing and debossing create raised or recessed designs on the box material. These techniques add a tactile element and create a visually appealing texture.

3.3. Foil Stamping:

Foil stamping involves applying a metallic or colored foil onto the box surface using heat and pressure. This technique adds a luxurious and premium look to the packaging.

4. Significance of Box Packaging Techniques:

4.1. Branding and Marketing:

Welldesigned and creatively executed box packaging can significantly impact a brand's visibility and sales. Unique packaging attracts attention, differentiates products from competitors, and communicates brand values to consumers.

4.2. Product Protection:

Proper box packaging techniques ensure that products are protected from damage during transportation and handling. The choice of appropriate materials, construction methods, and cushioning helps prevent breakage, moisture damage, and other potential hazards.

4.3. Consumer Experience:

Packaging plays a crucial role in enhancing the overall consumer experience. Easytoopen designs, attractive visuals, and functional features, such as handles or resealable closures, contribute to a positive perception of the product and increase customer satisfaction.

Conclusion:

Box packaging techniques involve a combination of design, construction, and decoration methods to create functional and visually appealing packaging solutions. Understanding these techniques and their significance in different industries can help manufacturers improve their product presentation, protect their goods during transit, and enhance their brand image.